Company Profile

An Integrated Service

Better Wear Welding offers an integrated mix of services which together reduces lead times, costs and project management; and improves control over quality. This in turn:

- reduces downtime

- increases efficiency

- delivers greater reliability with less machine wear and

- improves safety.

We have a proven track record in the successful delivery of projects across Australia. Every project we undertake is supported by a highly responsive team who can turn around jobs quickly and efficiently and without compromise to quality and safety.

Our Values

Key to our success is our people and the culture that we have built over decades. Our ethos built around productivity, delivering responsive and proactive solutions to our clients. Our values guild the way we work and provide a foundation integral to the way we do business.

Safety:

- Safety first

- Safety always

Teamwork:

- We work together

- We constantly improve.

Integrity:

- We listen

- We care

- We do what we say.

Results:

- We are solutions focused

- We go beyond the job.

People

We have a capacity to deliver in excess of 2,000+ man hours per week with the capability to increase as required. We have a can-do attitude, focused on solutions. We take the time to understand thoroughly the requirements, objectives and constraints of the job, and then work together to determine the best solution. As a result, we are often the ‘go to’ team for solutions.

Facilities

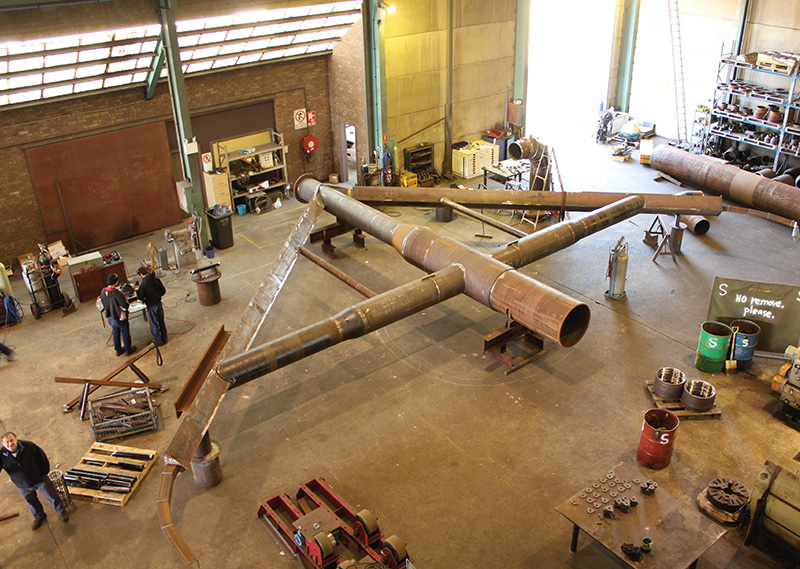

Better Wear Welding’s offices and workshop is strategically located in the heart of Midland, Perth, Western Australia. Our facilities are based

on an 18,200m2 lot area with a 3,400m2 workshop providing adequate area for the pre-assembly of components.

Our workshop is well equipped with the latest processing machines:

- Custom built hard facing machines for pipe hardfacing

- CNC pipe profiling machine

- Kinetic K4000 combination drilling and cutting machine including beveling

- Ficep Rapid Angle Line.

Projects we have completed include the:

- Worsley E&G – the fabrication and hardfaced works in excess of 250 spools for expansion

- Supply of 13 vibrating screens to Cape Lambert

- 2 x 20m thickener tanks for Christmas Creek.