3D Modelling, Drafting & Engineering

Better Wear Welding offers a one-stop-service with our capabilities in design, 3D modelling, drafting and engineering.

Together, our services offer greater control, reliability and overall better designs that translate to improved life of assets and cost savings as all aspects of a project or equipment is taken into account.

Capabilities

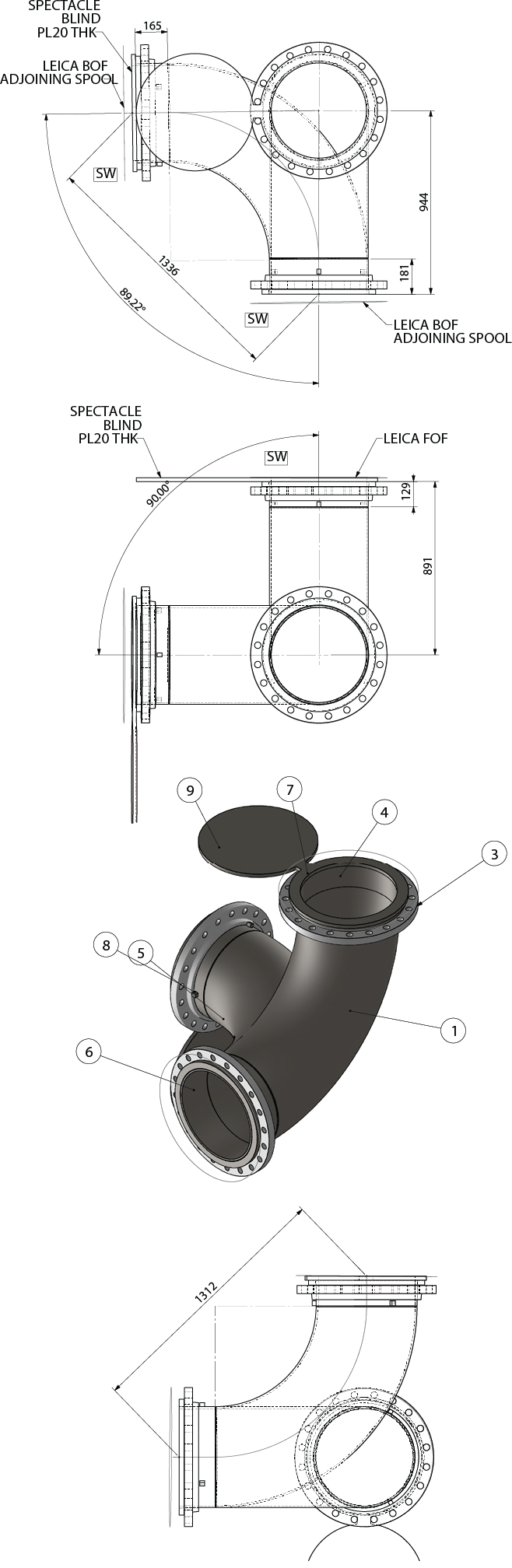

- 3D modelling for chutes, hoppers, structures, piping, tanks, pressure vessels

- Structural steel drawings using advanced 3D modelling software

- The utilisation of CNC files from our 3D design software to improve quality and reduce fabrication time

- Piping and steel structures modelled in 3D.

Our 3D models are fully detailed in accordance to design specification using the latest model of Inventor and Solidworks for detailing. This ensures the accuracy of information transferred for detailing, thus eliminating errors and increasing the speed of the fabricated drawing output.

With comprehensive 3D models, DXF/NC data can be generated and directly sent to respective CNC machines. This will ensure a level of high precision for all structural plate components in the manufacturing process. Any changes to the model will have a real time effect on any form of ECO – Engineers Change order.

On-Site

We can also measure components and provide as built drawings if a component differs from the original specification. If drawings are unavailable, we can go to site, measure and take the necessary data and dimensions, and then design and draw the components accordingly. We do all this in a timely manner to keep projects flowing.